Smart Stock Tracker

Stock Management Application with Detailed Insights

Modern Stock Tracking system to speed up tracking all of the stock materials that are found within warehouse, allowing users to track and export necessary reports

-

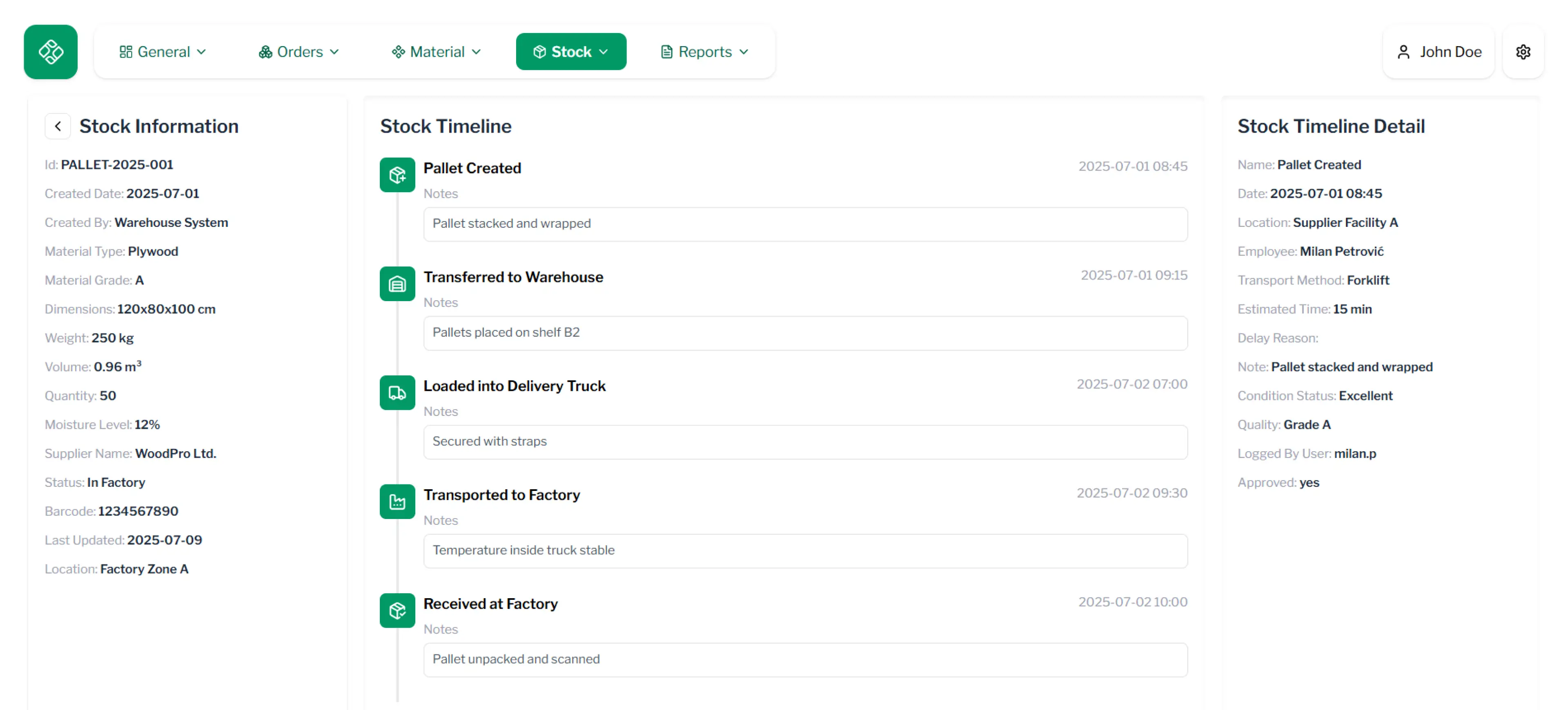

Stock Tracking

-

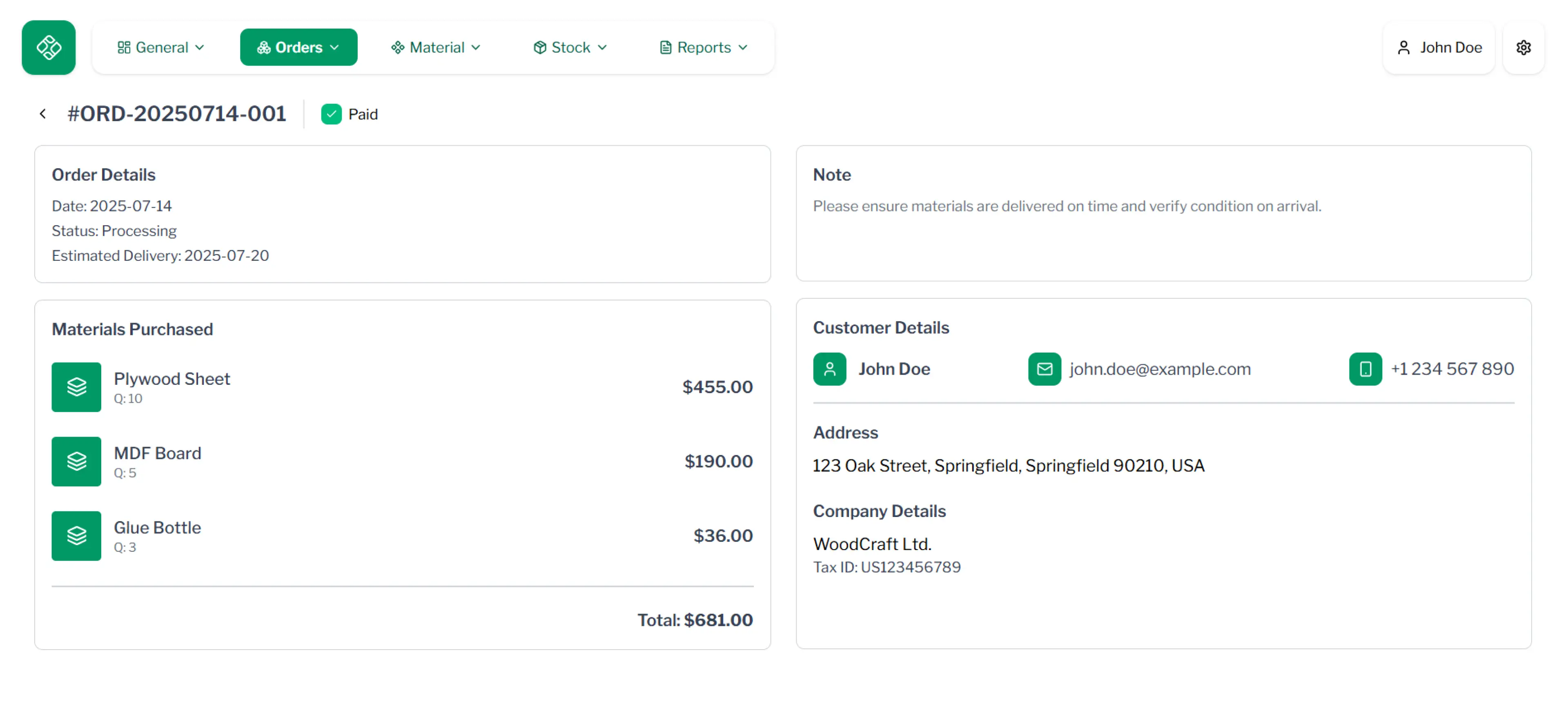

Order Tracking

Details

Project Overview

-

Smart Stock Tracker

-

Woodworking

-

2025

-

5 weeks

Agencies that manage their material inventory using paper logs or basic spreadsheets often struggle with outdated and incomplete stock information. The absence of a real-time system makes it challenging to anticipate shortages, causing delays when materials are unavailable. Additionally, tracking returned or partially used items becomes inconsistent, which disrupts planning, hinders timely delivery, and makes it harder to keep clients accurately informed

Challenges

Project Challenges

- 01

Manual Tracking

Materials were recorded manually using spreadsheets, which caused inefficiencies

- 02

Untracked Orders

Without a system, orders were not correctly tracked leading to discrepancies

- 03

Dispersed Materials

Delays caused by missing materials couldn’t be effectively communicated to clients

- 04

Difficult Forecasting

Missing automated alerts or reports caused struggles with stockouts or overstocking

Challenges

Solutions We Provided

-

Live Stock Dashboard

Real-Time efficient live Stock Management Dashboard to track orders and materials

-

Order Material Allocation

Material Allocation per order is precisely and automatically set when the order is created

-

Adjustable Orders

Extended feature to allow user to modify and adjust order based on real-time situation

-

Low Stock Alerts

Efficient background system to send notifications to re-stock when low stock is detected

-

Restock Input Form

Seamless interface where system automatically fills form for re-stocking the materials

-

Stock Reports

Accurate automated weekly and monthly reports with insight to materials and orders

Tech we used

.NET Core

ReactJS

PostgreSQL

Redis

Tailwindcss

Docker

Challenges

Project Summary

The lack of a digital inventory system and reliance on multiple handwritten logs led to inconsistent and fragmented stock data, making it difficult to get an accurate overview of material availability.

We began by thoroughly mapping the entire material flow process and developed a streamlined interface aligned with existing workflows. To improve data accuracy, initial stock records were carefully cleaned and migrated into the new system.

Manual adjustment features were incorporated to allow users to correct discrepancies during the early stages. The platform was designed to be user-friendly, enabling easy adoption by team members regardless of their technical experience.

Ready to Build Your

Success Story Together?

Send us a message today, and our team will get back to you promptly!

Let's Connect